Rain Bird introduced its QF Dripline Header, which is designed to speed the installation of drip irrigation systems by eliminating the need to build a PVC header. It allows for much faster and more precise installations of both on-surface and sub-surface dripline grids, according to the company.

“Compared to a site-built header constructed of PVC pipe, fittings, tape and glue, the time savings are significant,” said Chuck Kunze, Rain Bird product manager. “Based on time-motion studies of accomplished irrigation industry workers, each 100-foot coil of QF Dripline Header represents 3 ½ hours of labor savings. Simply roll out and make one cut to length—no more measuring, gluing or taping required.”

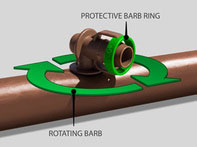

QF Dripline Header’s design features preinstalled fittings, compatible with any manufacturer’s 16 mm to 17 mm drip line, that rotate 360 degrees and incorporate a protective ring to prevent barb damage and ensure a proper seal, the company says. It is available in 100-foot, self-dispensing coils of ¾-inch or 1-inch tubing and with fitting spacing of either 12 inches or 18 inches.

QF Header can be used as either a supply or exhaust header and connects to the zone using standard ¾-inch and 1-inch compression fittings, lock fittings and insert fittings with clamps.

Photo: Rain Bird