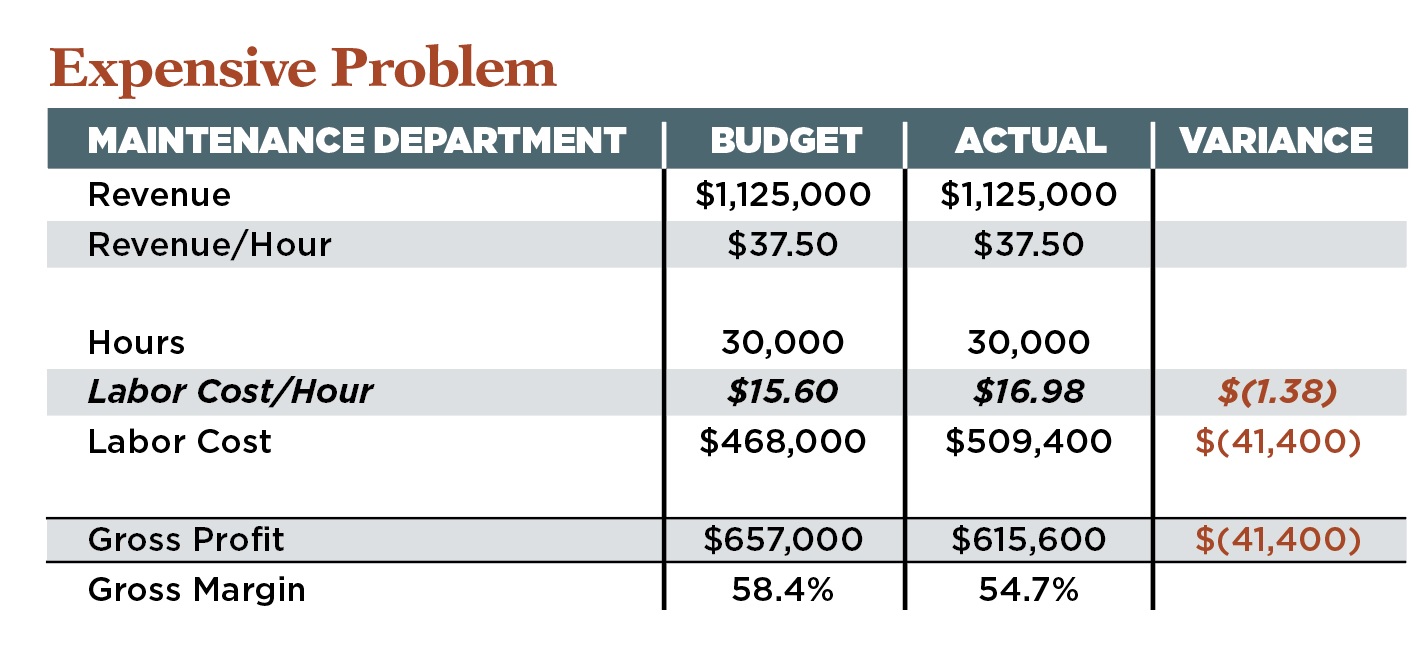

I was chatting with a client recently, and he posed the question, “How is it my crews are hitting job-hour budgets and our margins are down?” This is a common question we hear, especially when the focus is on achieving hourly over/under results. What’s often overlooked is the unit cost of those hours. This may seem obvious, but left unaddressed, it can become an expensive oversight (see “Expensive Problem” below).

Why does this happen?

The source of the problem is both macro and micro. The macroreason is the increasing cost of labor across the board. H-2B wage rates are higher than they have ever been, and a robust economy has increased competition for the same labor pool, as construction businesses outbid landscape companies for talent. The microreason has more to do with software and systems — specifically, bidding software and the labor rates established in the item catalogs of that software. These rates may be outdated and may not reflect real payroll rates. This problem is compounded by multiyear contracts and construction projects that were bid from six months to two years ago when payroll rates were lower.

What can you do?

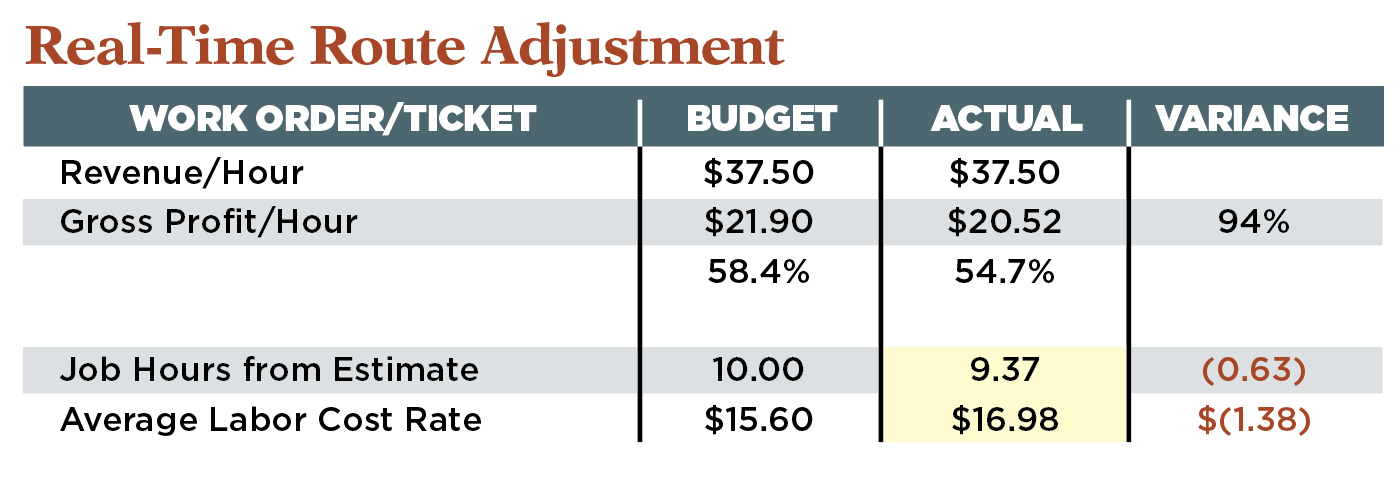

The first practice is catalog maintenance. You must establish a monthly process of reviewing actual average payroll data to “update” the hourly labor bid rate in your item catalog to ensure future proposals are priced at the most recent labor costs. In the “Real-Time Route Adjustment” table (below), the number to be updated is $16.98. The $15.60 rate is outdated. The $16.98 figure should be used as it is a more accurate cost rate.

The second practice is harder. It’s schedule and work ticket management. You must establish a daily process using actual jobs/work tickets on a schedule board. These job-hour budgets come directly from the job estimates. Every day when a crew clocks in to the software application, an actual average cost rate is calculated for the crew. This average crew-cost rate can be flagged when that rate is higher than the labor rate used in the estimate. This information provides the supervisor with the ability to decide whether to adjust job hours for the crew in order to maintain the original gross profit margin. In the “Real-Time Route Adjustment” table, that adjustment — using a 10-hour job as an example — is 9.37 hours. This means the allowable budget for the crew that day can’t be 10 hours; it has to 9.37 hours. If the crew were to use 10 hours, your over/under hour report would look just fine, but your gross margins would not.

I am not suggesting that quality issues and service issues are to be ignored. They cannot be. But at a minimum, you have some options for managing the gross margin. In fact, if this were a multivisit weekly maintenance contract, I would not only employ these strategies, I would create a “bank of hours” report to manage the margin over the entire contract time frame. It’s not a perfect system, but it is a good place to start.