When winterizing an irrigation system at season’s end, it’s critical not to overlook the pump and zone valves. Neglecting these components is one of the most common causes of costly cold-weather damage.

This oversight is common, especially for landscape and irrigation pros serving milder geographic zones where a deep, hard winter isn’t the norm, says Kurt Thompson, owner of K. Thompson and Associates, an irrigation troubleshooting, evaluation and planning company, and a partner and instructor at IrriTech Training.

“If you’re any place that has one or two days where the temperature doesn’t get above freezing, then you need to pay attention to pumps and valves,” Thompson says.

Force the air

The blowout is the industry standard for irrigation winterization. It involves a compressor to force air through each station sequentially until moisture is evacuated from the system.

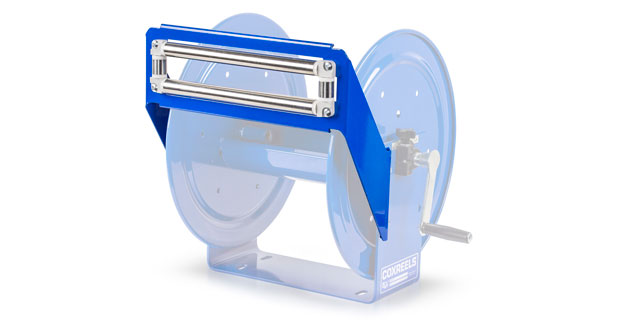

Beyond this basic blowout, contractors must focus on protecting the system’s more expensive components, such as booster pumps and filters, says Chris Rigby, senior contractor account manager for Rain Bird.

“The first priority is to ensure the ability to completely shut off the water supply, eliminating any standing water in the primary lines,” he says. Cast-iron pumps are highly susceptible to freezing damage, and Rigby strongly advises removing the existing drain plugs to thoroughly remove all water.

“Water trapped inside the cast iron housing, particularly around the impeller and its casing, will freeze, expand and exert immense pressure, causing catastrophic damage,” Rigby says.

In addition, irrigation pros caution contractors to avoid excessive pressure during the blowout. Matt Bruns, Toro’s district manager for the Midwest, suggests keeping it at around 50 psi for 10 seconds, as excessive air pressure can overheat and melt internal plastic components. Instead, prioritize air volume over pressure.

“While air can be compressed, water cannot,” Bruns says. “Therefore, the goal is not to use high pressure, but high air volume (cubic feet per minute) to push the water out of the system.”

If a contractor is unable to perform a complete blowout, then the only alternative is to open the system’s drain valves and ball valves, particularly in the manifold where the zone valves are located, to allow residual water to percolate out naturally.

Look at overlooked areas

Thompson stresses the need to drain the above-ground portion of the pump’s discharge line to prevent freeze damage. This line, which moves pressurized water from the pump and into the main pipes, is as critical to drain as the rest of the mainline.

Thompson adds that the suction or intake line is often overlooked. Since the line usually comes entirely out of the ground and into the pump, it must be drained. He warns, however, that the draining process can be complicated by a check valve or foot valve, which is designed to hold water in the suction line to prevent the pump from losing its prime.

“If this water-holding mechanism is in place, the water will be trapped in the line and can freeze, often splitting the pipe near the water level,” he says.

Rigby says filters, often made from plastic, must be emptied. He advises removing the bottom cap, often resembling an upside-down soda bottle, to drain the water. Additionally, removing the internal filter element is a good preventive measure, as residual moisture within the material can freeze and expand.

Necessary precautions

Regions that do not experience sustained, hard freezes should still employ a winterization strategy for pumps and valves. For above-ground metal elements, Rigby advises contractors to use pipe insulation wrapped and taped securely around the equipment to create a protective “pillow.” This provides just enough thermal barrier to prevent freezing during cold snaps.

Rigby notes that this insulation is beneficial year-round. It acts as a shield, preventing the sun’s intense heat from bearing down on plastic components, accelerating their breakdown and failure.

“While the insulation may make routine maintenance, like pressure checks, slightly more cumbersome, its value in protecting the system from both extreme cold and extreme heat makes it a worthwhile, year-round practice,” he says.