To extend the life of mowers and prevent costly repairs and downtime, owners need to ensure they’re properly maintaining their mower engines.

Not only does that keep mowers up and running, but it also results in happier customers, increased business and higher profit margins, says Jeff Turner, field service adviser with Kawasaki Engines.

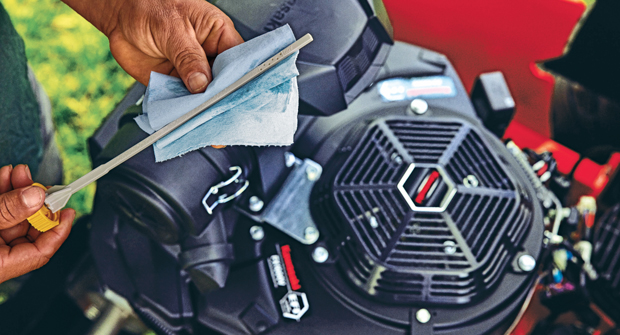

Checking the engine oil daily is vital because it could save owners thousands in repairs down the road, Turner says. With most mower engines being air-cooled, these machines also depend on clear, unobstructed airflow from the cooling fan and directed across the cooling fins.

“It not only makes your company look more professional to be on clean, well-taken-care-of equipment,” Turner says, “but it will greatly prolong the life of your engine because it will cool itself more efficiently when dirt and debris are not blocking off the cooling air.”

Clean air

Operators should follow the manufacturer’s recommendations for mower engine maintenance — including changing the engine oil and fuel and air filters, says Steve Stenz, turf product manager with Kohler.

“Inspect the engine after every use and ensure the engine is clean of debris on and around the engine — especially on the grass screen where cooling air enters the engine and the cooling fins on the engine block,” Stenz says.

If it runs in a dirty environment where the engine becomes plugged with debris, Stenz recommends looking over the engine. Owners should perform maintenance on the oil and clean the engine’s cooling fins to prevent any further damage.

It’s also important for owners to think about how they clean certain parts, Stenz says. For example, some owners make the mistake of taking the air filter out and using high-pressure air to blow the debris off of it.

“This is never good for the air cleaner and will create small holes in the paper media allowing dirt to bypass the filter,” Stenz says. “It is better to inspect the air filter and tap lightly to remove large debris and just replace when needed.”

Inspect for damage

Operators should check the mower engine for loose bolts and fasteners, along with fuel and oil leaks, says David Bush, assistant manager of shows, events and sponsorships with Honda Power’s sports and products division. The inspection might require tilting the equipment to see all sides of the engine to check the lower crank seal.

“Whenever tilting an engine, it is important to always tilt it away from the carburetor side,” Bush says. “This practice prevents any oil or gas from saturating the air filter and possible fuel leakage.”

If dirt or other contamination reach the fuel tank, it can clog the carburetor passages and affect engine performance.

Winterizing Engines Tips

After the last mow of the season, it’s time for owners to winterize their equipment.

“Old fuel or fuel left in the carburetor for months can cause gumming of the carburetor and the intake valve,” David Bush, assistant manager of shows, events and sponsorships with Honda Power’s sports and products division, says. “Even fuel that’s just a month old can make it hard to start the engine.”

To winterize a mower engine, users should change the oil and filters, add a fuel stabilizer to the tank, run the engine for five to 10 minutes, shut the fuel off and let the engine run at low idle until it stalls, Turner says.

“Once the engine stalls, I recommend pulling the choke and cranking the engine again while the fuel is still shut off,” Jeff Turner says. “This will pull any residual fuel through the small passages in the carburetor. Then drain the fuel tank and lines.”

EFI systems aren’t as prone to having fuel issues as carbureted, Steve Stenz, turf product manager with Kohler, says, but it’s still good to use stabilizer in the fuel with both systems.