In a previous article, I discussed how sprinkler precipitation rates vary between manufacturers and the impact that variability has on watering times and water use. In addition to variations between manufacturers, water managers need to be aware of three items that impact precipitation rates. Read more here: Know your sprinkler precipitation rate

1. Nozzle flow rate

The variation in water flow rate through sprinkler nozzles accounts for variation in precipitation rates between manufacturers. If every manufacturer produced spray nozzles with the same flow rate, the precipitation rate of all spray nozzles would be the same, regardless of the manufacturer.

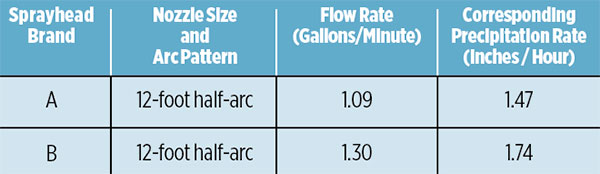

As flow rates increase, precipitation rates increase as well. The table below illustrates the difference in flow rates between leading manufacturers for the same size nozzle, both operating at 30 PSI.

The 0.21 gallon per minute (GPM) difference in nozzle flow rate between these two sprinklers seems minor, but when multiplied across 30 sprinklers on a single zone, the difference is 6.3 gallons for a single minute. When we multiply this across 60 minutes of watering per week in the summer, it amounts to a difference of 378 gallons in one week, just for one zone.

2. Sprinkler operating pressure

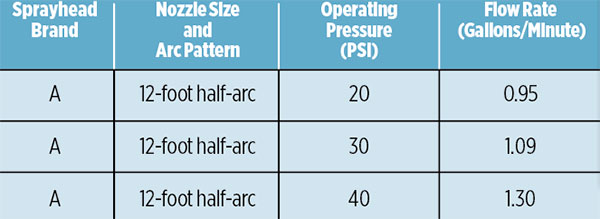

As sprinkler operating pressures increase, nozzle flow rates will increase. As mentioned above, as nozzle flow rates increase, precipitation rates increase. In a perfect system, the operating pressure at every sprayhead would be exactly the same, resulting in the same flow and precipitation rates at each sprinkler in a zone. The table at right illustrates the impact pressure has on spray nozzle flow rates for a leading manufacturer’s 12-foot, half-arc spray nozzle.

The use of sprinklers with in-stem pressure regulation devices maintains consistent operating pressures between sprinklers and uniform precipitation rates. In real-world conditions, system operating pressures that are significantly higher than the manufacturers’ recommended operating pressures result in misting and wind drift, which will result in lower precipitation rates to the targeted area.

3. Sprinkler spacing patterns

Most systems are designed with sprinklers spaced in either square patterns or triangular patterns. When sprinklers are spaced in a triangular pattern, the spacing is tighter with more overlap, resulting in a higher precipitation rate when compared to square spacing. Irrigation systems sometimes are designed with tighter spacing and more overlap to combat the impact of wind. Tighter sprinkler spacing will result in higher precipitation rates.

The items that impact the precipitation rate of a sprinkler can seem minor, but over time, across systems with hundreds of zones and thousands of sprinklers, the long-term impacts become enormous. Proper nozzle selection, correct sprinkler operating pressures and sprinkler spacing are important factors, especially when programming and managing smart controllers. To be an effective water manager, having a solid understanding of the items that impact precipitation is critical.