White clover, ground ivy, sedges and kyllinga can wreck havoc for LCOs. Eric Reasor, Ph.D., Southeast research scientist with PBI-Gordon Corp.; and Jesse Benelli, Ph.D., green solutions specialist for Envu break down what pros need to know and how to get a leg up on these perennial weeds.

Timing is key to white clover control

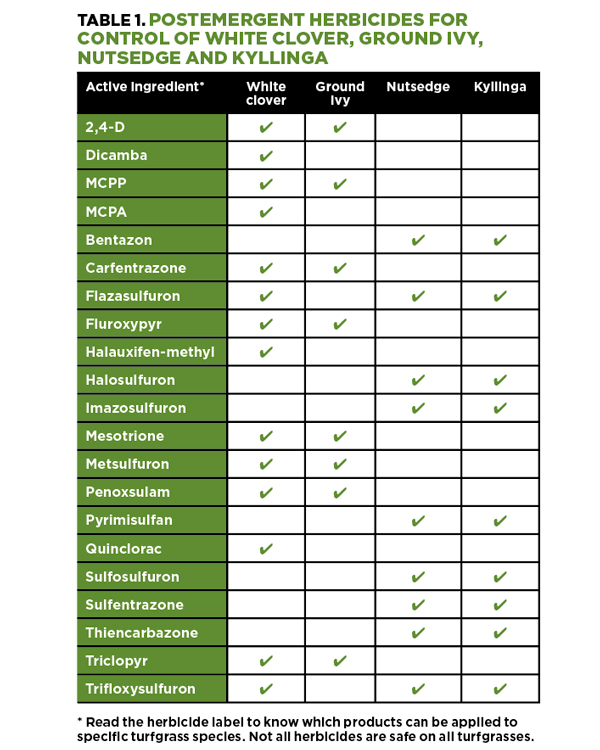

White clover is a persistent, perennial weed that grows between 50 and 75 degrees F. Make herbicide applications during active growth to maximize herbicide efficacy. Cooler weather and limited soil moisture can hinder herbicide activity. Be certain ambient air temperatures are conducive to herbicide activity by referring to the specific herbicide product label for application temperature ranges. Postemergent herbicides are most effective since it is a perennial weed. Many herbicide active ingredients can provide good white clover control (See Table 1).

Many products best for white clover control contain three or more active ingredients. Many of these products have active ingredients with multiple herbicide modes of action. It is essential to use multiple modes of action for herbicide resistance management. Herbicide resistance is not widespread in white clover; however, any weed can develop resistance to any herbicide.

LCOs have used many herbicides for white clover control for many years, and there is potential for herbicide resistance to develop or to see a decreased efficacy of active ingredients. Multiple herbicide applications are likely needed depending on the severity of the white clover infestation.

Proper treatment is key to long-term ground ivy control

Ground ivy is a perennial weed that is difficult to control in established turfgrasses and can grow throughout the summer and fall. Fewer herbicides effectively control ground ivy and applications made in spring or fall are recommended (Table 1). However, research from Purdue University has shown fall applications of fluroxypyr and metsulfuron are better than spring applications.

Herbicide application timing is important, but applying the appropriate active ingredients is more important for long-term control. Also, long-term control will likely require multiple herbicide applications depending on the infestation severity.

Sedges and kyllingas are fast growers

Sedges and kyllingas are difficult-to-control perennial weeds that survive the cold months as below-ground tubers and rhizomes. Often, these weeds proliferate more easily in low-lying areas and areas that receive excessive irrigation, yet we see tremendous surges in drought years with thinned turf. Both sedges and kyllingas are problematic because they grow faster than the surrounding turf and disrupt the visual quality and uniformity of the landscape.

Yellow and purple nutsedge are the most common species in turfgrasses that can be some of the first weeds to appear in the spring. It is essential to make herbicide applications in late spring and early summer (i.e., April, May and June) rather than late summer (i.e., July, August and September). Earlier applications limit the time for nutsedge tuber growth, which aids plants in outgrowing and surviving herbicide applications.

Not many herbicide active ingredients are labeled for nutsedge control (Table 1). It is essential to use multiple modes of action for herbicide resistance management. You can control sedges and kyllingas with postemergence herbicides formulated with one or more ingredients. Products with multiple active ingredients eliminate the need for tank-mixing products, reducing the risk of mistakes.

Timing your initial postemergence herbicide application is critical. Recent research suggests you should make postemergence herbicide applications for sedges at the two- or three-leaf stage for the most effective long-term control, and timing for kyllingas would be similar. Typically, this occurs in mid-to-late spring throughout much of the Southeast and transition zone.

You will need multiple herbicide applications for long-term nutsedge control, especially with contact herbicides such as sulfentrazone and bentazon. A second application should be five to seven weeks after the initial application. Include a nonionic surfactant at 0.25 percent volume per volume for optimal control (do not include a surfactant when ambient air temperatures exceed 90 degrees F coupled with high relative humidity).